H-2984.XX

Pundit Lab, Ultrasonic Test Device

Used to detect the presence of cracks, voids and imperfections in concrete

HC-6320

Pundit Ultrasonic Pulse Velocity and Echo

The Pundit Ultrasonics are specifically designed to be used on-site and harsh environments

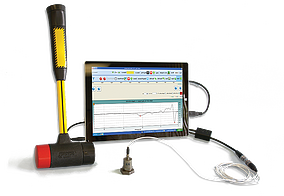

HC-6485

Sonic Echo Foundation Tester

Measuring the depth and integrity of drilled shafts, driven piles, concrete mats, and timber foundations

H-2880

Concrete Thickness Gauge

The Concrete thickness gauge measures concrete slab thickness without drilling

HC-6440

Cross Hole Ultrasonic Monitor

Basic CHUM package includes everything required to perform CSL and 2D tomography

HC-6390

Ultrasonic Pulse Velocity Tester

Used to determine the presence of faults, voids, cracks and more

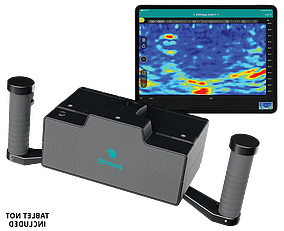

HC-6465

Pundit Ultrasonic Pulse Echo, PD8050

The wireless inspection solution with multi-channel ultrasonic pulse echo technology, brings on-site structural concrete assessment and imaging to the next level.

Ultrasonic Testing

Ultrasonic testing of concrete is an in-situ, nondestructive test to check thickness measurements of concrete and tunnel linings; determining localized defects such as voids, honeycombing; depth and extent of delaminations, and the detection of objects in the concrete such as pipes and tendon ducts beyond the rebar layer. Ultasonic testing can also be used to monitor the strength and deterioration of concrete, which may have occurred due to age, fire, frost or chemical attack.

Ultrasonic testing is conducted by passing a pulse of ultrasonic waves through the concrete to be tested and measuring the time taken by the pulse to get through the structure. Higher velocities indicate good quality and continuity of the material, while slower velocities may indicate concrete with many cracks or voids. Ultrasonic Pulse Velocity has proven to be an effective non-destructive testing method for quality control of concrete materials and detecting damages to structural concrete. This testing method is outlined in ASTM D597.

The concept behind the technology is based in the measurement of the travel time of acoustic waves through concrete, and correlating them to the known elastic properties and density of the material. The travel time of the ultrasonic waves reflects the internal condition of material. In general, for a given trajectory, higher travel times correlate to low-quality concrete containing anomalies and deficiencies, while lower travel times correlate to high-quality concrete with fewer anomalies.

Humboldt provides a wide selection of ultrasonic testing equipment from several manufacturers to choose from. If you have questions or need help selecting equipment, please call us at 1.800.544.7220 or use our Ask Humboldt form.

Click here to learn more about non-destructive testing principles and testing techniques.